Meet our project partner GOIMEK

As part of DANOBATGROUP, that have more than 50 years of experience in supplying high precision equipment and innovative solutions to various industry sectors, GOIMEK are specialised in high-accuracy part machining with the highest standards of quality and service.

GOIMEK use state-of-the-art technology and high precision, high output machines, complemented by the latest-generation verification resources. Moreover, they offer complete solutions, which are based on the best options in terms of cost, material, weight, environmental impact and the production process required by the sector.

Arkaitz Aranburu

The role of GOIMEK in the project

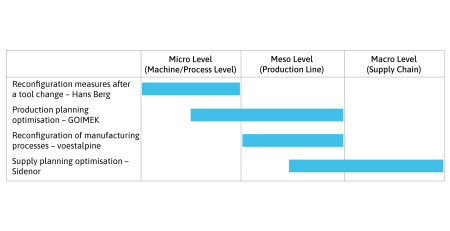

Within Flex4Res, GOIMEK provide a use case scenario about production planning optimisation. Learn more about the use case with GOIMEK: https://www.flex4res.eu/pilots/goimek/

GOIMEK is part of Flex4Res, because…

… all operations of GOIMEK are performed in several working centres. The process steps are flexible but need to be fixed according to the daily production needs. Based on data from the ERP system a master production plan is generated, which is manually turned into a final production plan.

With their participation in the Flex4Res project, GOIMEK wants to improve their resilience on the plant as well as machine level. Flex4Res aims to enhance resilience within the GOIMEK use case on two crucial levels: plant and machine. On the machine level, the focus is on elevating resilience through the implementation of advanced monitoring and anomaly detection functionalities, improving both machine condition and the machining process. Simultaneously, at the plant level, the aim is to enhance overall resilience by optimising production planning and including communication with the machine level.