Data spaces for flexible production lines & supply chains

For resilient manufacturing

In the rapidly evolving digital landscape, challenges like the COVID-19 pandemic have forced manufacturers to rethink not only their supply chains but also the adaptability of their production facilities. Achieving resilient manufacturing is crucial to maintain high-quality production at efficient rates while reducing non-value-adding activities.

The European research project Flex4Res, which stands for Data spaces for FLEXible production lines and supply chains FOR RESilient manufacturing, concentrates on making supply chains more resilient.

To achieve this, Flex4Res develops an open platform for secure and sovereign data exchange along the supply chain that supports the reconfiguration of production networks. It also develops two toolboxes: one for resilience assessment and one for reconfiguration planning. These toolboxes allow different players in the supply chain to effectively and rapidly adjust to various disruptions, both in their supply chains and production processes.

Key dates

Use cases

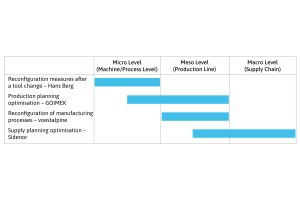

The integrated solution will be tested and validated in four industrial use cases on the reconfiguration of different hierarchical layers, from the value chain to machines and devices.

Hans Berg GmbH & Co. KG

Challenge: Adjustment measures are necessary when a tool or material has changed, but its duration and success depend on the experience of the employee executing it.

Goal: Reducing the time required to reconfigure the tools, the amount of produced defective components, and the need for the experience required to perform the adjustment tasks.

Sidenor Group

Challenge: Disruptions require reallocating the production, which takes place manually. Decisions taken at network level aren’t connected to the reconfiguration needed at the factory level.

Goal: Reducing the time required for reconfiguration of the production plans for the production network by supporting the user throughout the reconfiguration planning.

GOIMEK

Challenge: The process steps within the production of one part are performed in several working centres. They need to be fixed according to the daily production needs.

Goal: Increasing the efficiency and competitiveness as well as the predictability of production by developing a cross-site production planner, which can be constantly reconfigured.

voestalpine High Performance Metals Digital Solutions GmbH

Challenge: The products vary in size and shape and can only be machined on machinery providing the necessary capabilities, which also vary on other factors such as tools.

Goal: Highly flexible production planning and scheduling, also depending on the current machine state and manufacturing utilities with the opportunity to reconfigure the processes during production.

Latest updates

Project partners

17 partners from 6 EU countries (Austria, Belgium, Greece, Luxemburg, Germany and Spain). The number of different countries in the project ensures a rounder approach to the problems that are met by different European countries.